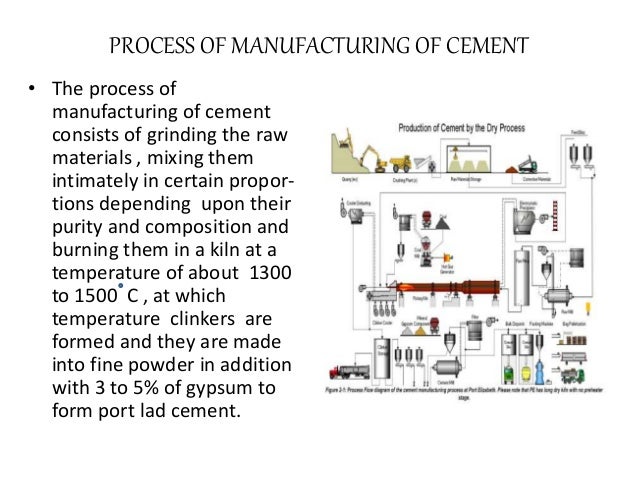

A site engineer will often order a different type of mix for a different purpose. A good mix designer will start with the properties that are desired in the mix, then take many factors into account, and work out a detailed mix design. Working out the exact 'recipe', or proportions of each ingredient is a science in itself. During this time the concrete must be cured, or supplied with water on its surface, which it needs for the chemical reactions within to proceed properly. Therefore it is usually propped up until that period. The concrete will become hard in a matter of hours, but takes a month to reach its full strength. Once the steel is in place, one can start to prepare the concrete, by mixing cement, sand, stone chips in a range of sizes, and water in a cement mixer, and pouring in the liquid concrete into the formwork tilll exactly the right level is reached. The tied steel is called a reinforcement cage, because it is shaped like one. Then one looks at the structural engineer's drawings and places in the steel reinforcement bars, and ties them in place using wire. To make reinforced concrete, one first makes a mould, called formwork, that will contain the liquid concrete and give it the form and shape we need. This combination works very well, as concrete is very strong in compression, easy to produce at site, and inexpensive, and steel is very very strong in tension. RCC is concrete that contains steel bars, called reinforcement bars, or rebars. Its full name is reinforced cement concrete, or RCC.

The ancient Egyptians used a lime and gypsum mixture very similar to modern concrete as early as 3000 B.C., and opus caementicium was used throughout the Roman Republic.When we say concrete in the building trade, we actually mean reinforced concrete.

After it dries, you essentially have a custom-sized slab of rock - only without having to cut blocks of stone out of the Earth.

Someone drives up in a truck, pours the gritty, wet concrete into the desired area and workers shape and smooth it into place. Even at gunpoint, that requires some serious conversational talent. First, you have to make sure you have the right proportions in your concrete mixture and then you have to convince the intended victim to keep still for a few hours while it hardens around his or her feet. After all, it looks pretty simple in "Billy Bathgate." However, if the movies teach us anything about the ins and outs of the criminal underworld, then fitting a doomed gangster with concrete shoes is obviously a far from simple undertaking. Maybe you've never had to send a rival mobster to the bottom of the East River and, therefore, can't fully appreciate the craftsmanship. Few professions are as unappreciated as that of the gangland concrete shoe cobbler.

0 kommentar(er)

0 kommentar(er)